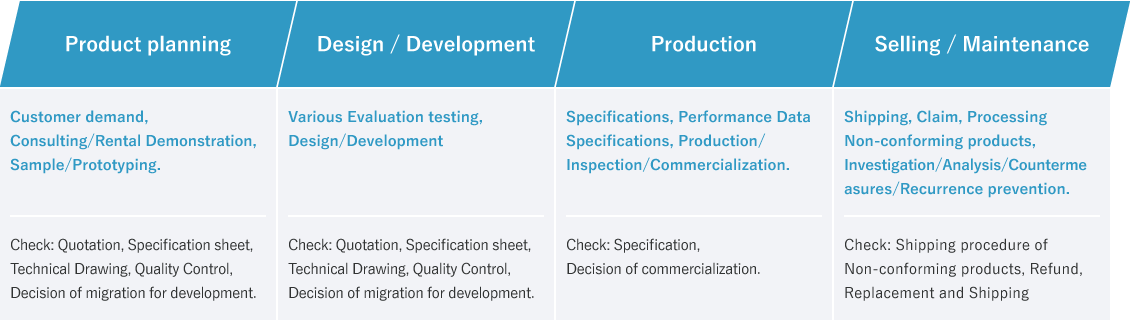

Quality Management

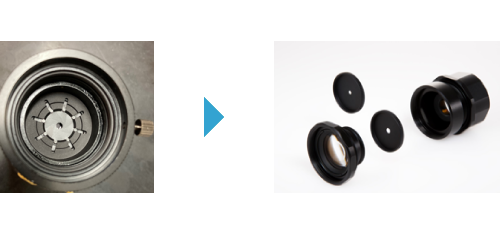

To meet the demand for “high-mix, low-volume” products, we will outsource the manufacturing section based on cell production.

We will establish a comprehensive operation and management system, and conduct our own quality inspections in line with the application.

Various optical evaluation and testing equipment will be fully equipped to ensure higher quality control.

Warranty

【Duration of Warranty】

| Machine Vision Lenses/FA Lenses |

All catalog products | 1 year |

|---|---|---|

| Surveillance Lenses | ||

| Lighting | VL-series | 2 years |

| VLP-series | ||

| VLC-series | 1 year |

【Terms of Warranty】

- Under the warranty, VST Corp.

shall replace or repair the defective parts or replace products without any charge,if failure or defection should occur during ordinary use.

This warranty does not cover products under the following conditions.

VST shall not be responsible for the following conditions:

- ① The damages resulting from external causes including accident of fire, earthquake, flood,thunderstorm ,electrical surges, and other natural disaster.

- ② The products have been broken-down or damaged as the result of dropping or other impact, due to inappropriate handling.

- ③ The damage caused by the connected to the product.

- ④ The products which have been subjected to improper repair, modification or altered by anyone other than VST.

- ⑤ The damage caused by the reasons which nobody could predict due to limitations of technology in the time of shipment or the contract between

- ⑥ The collateral damage such as the loss of business interests or business interruption caused by the use of products or the unusable goods.

- ⑦ The impediment or loss such as a late ot lost package and etc. attribute to export contracts.

【Preliminary Note】

- Please note that we will announce you 3mounths in advance on our website in the case that we discontinue the products or change the specifications of the products in this catalogue and we will integrate to subsequent model.

VST anti-vibration assurance standard

VS Technology will maintain and verify the performance of each lens under our regulated conditions and shipping standards to provide reliable products for our customers.

Guaranteed environment condition

| Operating temperature / humidity range | -5℃~50℃ | 80% Non-condensing |

|---|---|---|

| Storage temperature and humidity range | -10℃~60℃ | 90% Non-condensing |

Shock test conditions

| Acceleration | Duration of action | Number of impacts |

|---|---|---|

| 10G | 11ms | 3 times × 6 Directions |

In accordance with JIS C 60068-2-27

Vibration test condition

Click here for the vibration assurance comparison table for each series

| Acceleration(G) | Frequency(Hz) | Total amplitude(mm) | Sweep rate | Test direction | Test time | ||

|---|---|---|---|---|---|---|---|

| 3 | 7 | 55 | 0.49 | 30.40 | 15sec one side | X direction, Y direction | 5H / direction (10H in total) |

| 20 | 17 | 55 | 3.28 | 34.36 | 15sec one side | X direction, Y direction | 5H / direction (10H in total) |

In accordance with JIS C 60068-2-6

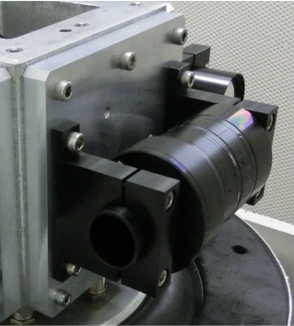

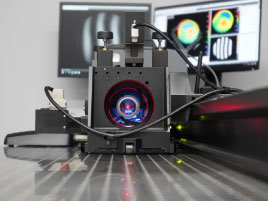

Shock resistance and vibration resistance test

The lens is tested for shock and vibration resistance by subjecting it to impact and vibration as shown in the image below.

Images are verified prior to and after the inspection to confirm that they meet our standards.

Shockproof

Vibration resistance

For problems with strong vibration/shock

Inspection is available for vibration and shock resistance in an environment that matches the customer’s usage conditions.

We can also perform inspections under conditions other than those specified in our standards, so please feel free to contact us.

Proposal of vibration and impact resistance

We understand that there are various concerns depending on the use conditions of our customers.

Based on our experience and expertise, we will make a proposal tailored to your needs to maximize the performance of our products under typically difficult operating conditions.

Dropout prevention

Customer Consultation

solution

Dust suppression

Customer Consultation

solution

Proposal of mechanism including clamp

Customer Consultation

solution

Other quality control inspection items

We have a full range of optical evaluation and testing equipment, and conduct our own quality inspections in order to maintain high quality.

-

MTF measurement device

It is a device that measures the imaging performance of a lens and shows how faithfully the contrast can be reproduced as a spatial frequency characteristic.

number of units carried (in inventory):3

-

Interferometers

It is a device that uses light interference to measure the wavelength, length (distance), surface shape, and refractive index of light.

number of units carried (in inventory):2(Zygo・FUJINON)

-

Environmental test chambers

This equipment is used to test the properties of products by reproducing the environment of temperature and humidity.

number of units carried (in inventory):3

-

Resolving power projection inspection machine

An inspection machine that measures the resolving power of a lens.

number of units carried (in inventory):8

-

CTF measurement device

An inspection device (in-house equipment) that measures the contrast of a lens.

number of units carried (in inventory):10

-

Eccentricity measuring system

This device measures the eccentricity of the outer diameter and optical axis of a lens.

number of units carried (in inventory):3

-

Precision dimension measuring microscope

This inspection machine measures dimensions by magnifying the measurement target beyond visual inspection.

number of units carried (in inventory):3

-

Electrodynamic Vibration Test Systems

This equipment is used to perform vibration evaluation tests by generating forced vibration set to an arbitrary force, acceleration or frequency, and by vibration loading.

number of units carried (in inventory):1

-

XRF Analyzer

It is a device that irradiates an object with X-rays and analyzes the substance by the energy difference of the X-rays emitted from the object.

number of units carried (in inventory):1