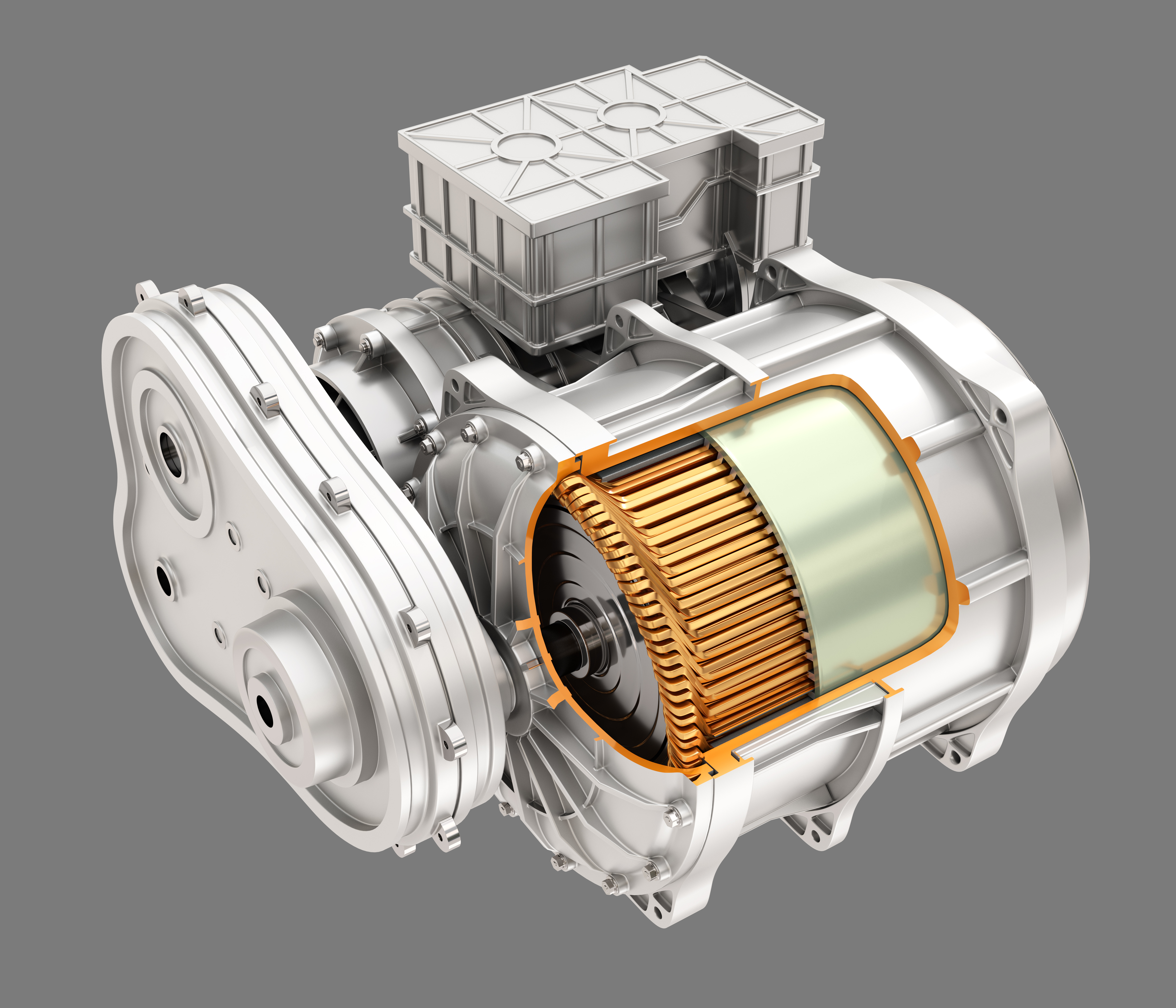

Visual inspection of large automotive parts.

Visual inspection using a multi-axis robot arm combined with a lens.

A single part has multiple inspection points, each of which is uneven and requires focus adjustment in multiple directions.

What is the product that can handle visual inspection that requires focus adjustment?

●Installed Product

Case Study Digest

| Challenges/Issues | VS-FT12HV Evaluation |

|---|---|

*It is necessary to inspect multiple areas in one large part. |

・The use of a liquid lens allows the robot to focus at any position, and reduces the number of man-hours by minimizing the need to adjust the robot in the direction of the focus axis. |

Challenges/Issues

*It is necessary to inspect multiple areas in one large part.

*For a standard lens, the focus surface of the lens is fixed. Therefore, it is necessary to move the robot arm to the position where the lens is in focus.

VS-FT12HV Evaluation

・The use of a liquid lens allows the robot to focus at any position, and reduces the number of man-hours by minimizing the need to adjust the robot in the direction of the focus axis.

・Cycle time can be improved by controlling the focus through current control rather than running a robot arm.

| About the VS-FT12HV selected to solve the issue in the case study. | |

|---|---|

|

Built-in Liquid Focusing /Optimized for 12MP 1.1″ ・1.1”, 3.45μm resolution support |

About the VS-FT12HV selected to solve the issue in the case study.

Built-in Liquid Focusing /Optimized for 12MP 1.1″

Wide Angle Fixed Focal Length Lens

・1.1”, 3.45μm resolution support

・Large Angle of view with 1.1″ sensor

・Able to adjust focus from 150mm to infinity

※Liquid focusing lens driver and cables are optional products

Related Product

-

- Focus Adjustment

VSZ-MR Series

Specifications, Drawings

Specifications, Drawings -

- Focus Adjustment

VS-LQL Series

Specifications, Drawings

Specifications, Drawings