-

Ring Lighting

Achieved in one housing without compromising the features of three ring lights

-

Diffused Lighting

High brightness, high uniformity, making unevenness difficult to see, ideal for printing inspection, etc.

-

Bar Lighting

Lighting that has a high degree of freedom in size and is easy to use regardless of the size or purpose of the work.

-

Coaxial Lighting

High-brightness type with miniaturization and shortWD compatible, all models are light leakage countermeasures

-

Spot Lighting

Optimized uniformity and light distribution characteristics for VST lens lighting

-

Surface Lighting

Compact design, high brightness and high uniformity, can be customized to any size at the same size

-

Collimated Lighting

Spot illumination with high telecentricity is possible

-

Power/Controller/Cable

Extension /External control Cable

-

Special Lightining for Lens Combination

Dedicated lighting designed for the challenges faced by each lens

-

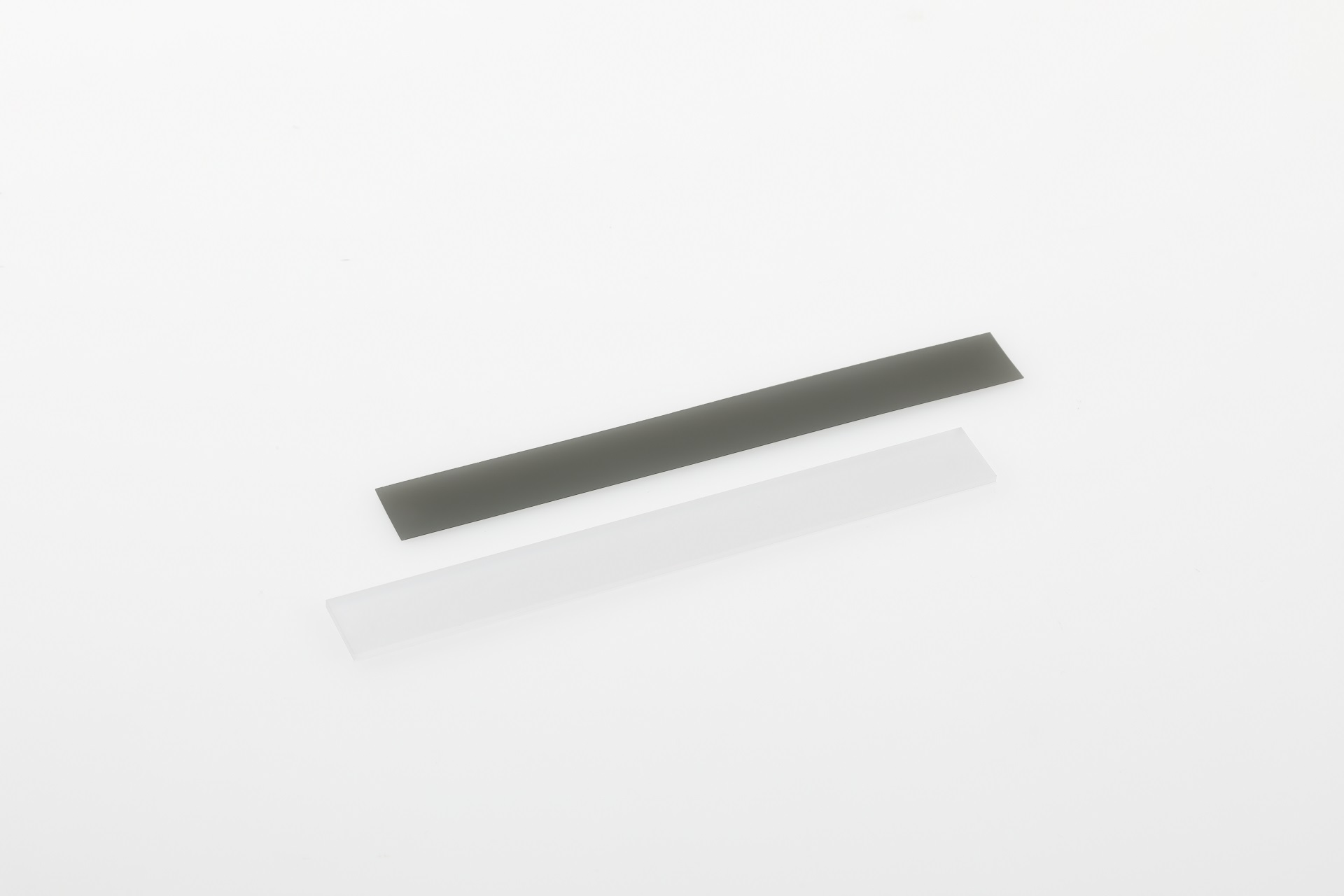

Option

Diffuser/Polarizer plate

VS Technology LED Lighting